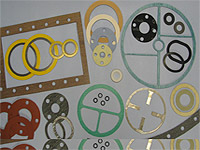

Gaskets & Seals

Gaskets are versatile mechanical seals that prevent fluid or gas leaks between connected components. Potter Associates, Inc., is a leading gasket supplier, offering a variety of high-quality gaskets. Our extensive inventory includes standard, specialty, and custom gaskets in a range of materials. Our in-house gasket-cutting capabilities help us create and deliver your custom gaskets quickly, providing you with the sealing solutions you need when you need them.

For more information about high-quality custom gaskets and additional products, contact Potter today to speak with an industry expert.

Gasket Compounds & Materials

While gaskets are often made from rubbers and elastomers, various materials such as metal or plastic are also used for sealing applications. At Potter, we supply gaskets in over 25 materials, from rubber to ceramic to fiberglass and more. Common rubber gasket materials include but are not limited to:

- Buna

- Butyl

- Cork Blend

- EPDM/EPR

- Neoprene

- Nitrile

- PTFE

- And More!

Types of Gaskets

There are many different styles of gaskets, each designed to meet specific application standards. Properties of gaskets vary between styles and include factors such as flexibility, compressibility, chemical resistance, and temperature tolerances. Gaskets that fulfill the requirements for one project may prove ineffectual for a different application. With our large selection of gasket types and styles, Potter is proud to be your one-stop shop for all your gasket and sealing needs. Gasket styles from Potter include but are not limited to:

- FDA Sanitary Gaskets

- Flange Gaskets

- Metal Gaskets

- Non-Asbestos Gaskets

- OEM Replacement Gaskets

- Ring Gaskets

- And More!

Industries Served

Available in a wide range of styles, materials, shapes, and sizes, gaskets are used in virtually all industries for sealing applications. Industries served include but are not limited to:

- Industrial Manufacturing

- Food & Beverage

- Chemical Processing

- Power Generation

- MRO (Plant Maintenance & Repairs)

Potter is your #1 Rubber Gaskets Supplier & Distributor

At Potter, generations of expertise and experience have been passed down to help us transform into a leading gasket distributor. We work with respected manufacturers to supply you with premium products and solutions. No matter your gasket application, we can find the best solution for you. Request a quote to begin your order today, or contact us for more information, and we will happily answer any questions.